Grade 9 Titanium Guide

Ti-3Al-2.5V

Overview: Grade 9 is a titanium alloy with the composition Ti-3Al-2.5V – sometimes referred to as “half 6-4" because its aluminum and vanadium content are roughly half that of Grade 5's 6% and 4%. It's also known by trade names like Ti-3-2.5 or ASTM Grade 9. This alloy is an alpha-beta titanium, but leans more toward the alpha side due to lower beta stabilizer content. The result is a medium-strength alloy that stands between CP titanium and Grade 5 in strength, but with excellent cold workability and weldability. Grade 9 is especially famous for use in titanium tubing.

Overview: Grade 9 is a titanium alloy with the composition Ti-3Al-2.5V – sometimes referred to as “half 6-4" because its aluminum and vanadium content are roughly half that of Grade 5's 6% and 4%. It's also known by trade names like Ti-3-2.5 or ASTM Grade 9. This alloy is an alpha-beta titanium, but leans more toward the alpha side due to lower beta stabilizer content. The result is a medium-strength alloy that stands between CP titanium and Grade 5 in strength, but with excellent cold workability and weldability. Grade 9 is especially famous for use in titanium tubing.

Mechanical Properties:

In annealed condition:

Ultimate Tensile Strength: ~90 ksi (620 MPa) typical. Spec minimum is around 80–90 ksi depending on product form.

Yield Strength: ~70 ksi (483 MPa) typical. (So much higher than CP Grade 2's ~40 ksi, but about 60% of Grade 5's ~120 ksi.)

Elongation: ~15–25%. It's more ductile than Grade 5, which aids in formability.

Modulus: ~103 GPa (15.0 Msi) – basically in the same ballpark as other Ti alloys.

Density: ~4.48 g/cc (0.162 lb/in³), very close to CP Ti.

These properties can vary if the material is cold-worked (Grade 9 is often available in a cold-worked stress-relieved condition for tubing, which bumps the strength up a bit).

Why Grade 9?

The key feature is strength vs formability: Grade 9 has about 20–30% higher strength than Grade 2 while still being readily cold-formable and weldable. Grade 5, by contrast, is difficult to cold-form. So Grade 9 is ideal for products that need to be formed or welded into shape and still require more strength than CP titanium. It also has very good fatigue strength, making it great for cyclically loaded parts (like bike frames).

Common Applications:

Tubing: Grade 9 is the material for high-performance titanium tubing, especially in aerospace (for hydraulic lines) and sports equipment (for bicycle frames). Its combination of moderate strength and easy fabrication means it can be drawn into thin-wall tubes and bent without cracking. For example, many commercial aircraft use Grade 9 seamless tubes for fuel and hydraulic systems. And if you see a sleek titanium road bike, its tubes are very often Grade 9. The tubing can be welded to build the frame, and it handles the dynamic stresses of riding very well.

Tubing: Grade 9 is the material for high-performance titanium tubing, especially in aerospace (for hydraulic lines) and sports equipment (for bicycle frames). Its combination of moderate strength and easy fabrication means it can be drawn into thin-wall tubes and bent without cracking. For example, many commercial aircraft use Grade 9 seamless tubes for fuel and hydraulic systems. And if you see a sleek titanium road bike, its tubes are very often Grade 9. The tubing can be welded to build the frame, and it handles the dynamic stresses of riding very well.Sheet Metal Forms: While less common than tubes, Grade 9 sheet can be used when you need to stamp or deep draw a part that's stronger than CP Ti. It's known to be workable in sheet forming to some degree (though still stiffer than steel or aluminum in that regard).

Heat Exchangers: In chemical and power plants, Grade 9 is used for heat exchanger tubes that operate at somewhat higher pressures than Grade 2 could handle, yet still need great corrosion resistance. It's like the upgraded CP titanium for when a stronger tube is necessary.

Recreational Equipment – Beyond bikes, things like titanium camping gear, motorcycle exhausts, and even golf club shafts sometimes use Grade 9 – any application needing a mix of strength and ductility.

Comparison:

Vs Grade 5: Grade 9 is weaker (UTS ~620 vs 950 MPa) but significantly more formable. It can be cold-rolled and drawn, whereas Grade 5 often needs hot working. So Grade 9 won't replace Grade 5 in applications where maximum strength is needed (e.g., engine parts), but it shines when you need to make something like a thin-walled tube that Grade 5 would crack during manufacturing.

Vs CP Grades: Grade 9 offers a clear strength bump with only a slight drop in ductility from CP. It's like a “strong CP titanium." Corrosion-wise, Grade 9 is still excellent (the small V and Al additions don't compromise corrosion too much in most environments). If Grade 2 isn't strong enough for a pressure-containing part, designers often turn to Grade 9 as the next step before considering a fully alloyed grade.

Vs Beta alloys: Grade 9 is easier to weld and work with than most beta alloys, and doesn't require aging heat treatments. It's a more practical choice for moderate strength needs.

Availability:

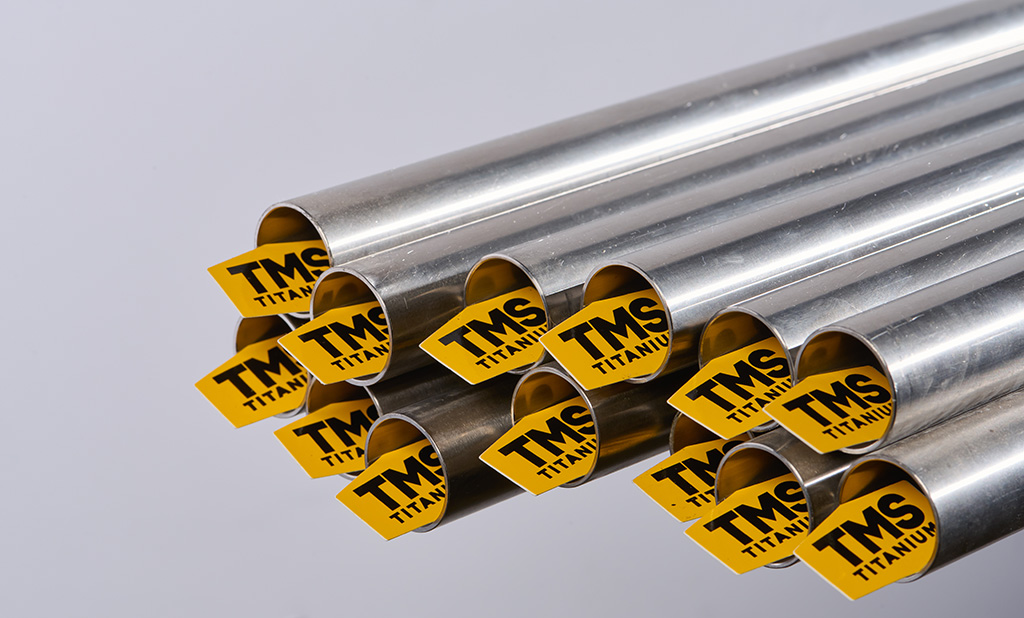

Grade 9 is most commonly found as seamless tubing. At TMS, titanium tubing in Grade 9 is popular among our racing and bicycle industry customers. You can also get Grade 9 in sheet/plate and bar forms, though those might be special order as demand is lower than for Grade 5 or CP.

Welding:

Grade 9 is readily TIG welded, similar to CP titanium. It doesn't suffer from the high crack sensitivity that some higher-strength alloys do. That's one reason it's chosen for bike frames – welds are tough and reliable (with proper argon shielding of course).

Fun Fact: Grade 9 got a spotlight in sports when titanium bikes took over the high-end bicycle market. In the 1990s, Merlin and Litespeed (pioneering titanium bike manufacturers) popularized Grade 9 titanium frames. Riders rave that the slight flexibility of titanium gives a unique ride comfort (often called the “ti magic carpet ride"), yet it's stiff enough for efficient power transfer. And here's something cool – some ultralight titanium wheelchair frames for Paralympic athletes are made of Grade 9 tubing, giving them both strength and a bit of flex for comfort, at a weight that's easy to propel.