Grade 2 Titanium Guide

CP Titanium Grade 2

Overview: Grade 2 is the most commonly used commercially pure titanium grade. It offers an excellent mix of strength, ductility, and corrosion resistance, making it the go-to pure titanium for industrial and medical applications. Grade 2 titanium is essentially unalloyed Ti (~99% Ti) with a small amount of oxygen (~0.2–0.4%) and iron (~0.1%) as impurities that give it moderate strength. It is sometimes called “Titanium 50A" (in ASTM specs) or just “CP-2" titanium.

Overview: Grade 2 is the most commonly used commercially pure titanium grade. It offers an excellent mix of strength, ductility, and corrosion resistance, making it the go-to pure titanium for industrial and medical applications. Grade 2 titanium is essentially unalloyed Ti (~99% Ti) with a small amount of oxygen (~0.2–0.4%) and iron (~0.1%) as impurities that give it moderate strength. It is sometimes called “Titanium 50A" (in ASTM specs) or just “CP-2" titanium.

Mechanical Properties:

In the annealed condition, Grade 2 Titanium has:

Ultimate Tensile Strength: ~50–75 ksi (345–515 MPa) typical. Minimum spec is usually 50 ksi (345 MPa), but often material is stronger toward 70+ ksi.

Yield Strength: ~40–55 ksi (275–380 MPa). (It's stronger than Grade 1 but lower than any alloyed grade.)

Elongation: ~20–30% (quite ductile, can deform significantly before breaking).

Modulus of Elasticity: ~105 GPa (about 15.2 Msi, same order as all titanium grades).

Hardness: Around Rockwell C 20 (very roughly; often given in Rockwell B ~80).

Density: 4.51 g/cc (0.163 lb/in³), same for all CP grades.

Note: Grade 2 is not hardenable by heat treatment – only cold work can strengthen it (aside from minor solid-solution strengthening from those impurities).

Chemical Composition:

Ti ≥ 99%, O ~0.25% (max 0.25 for Grade 2 spec), Fe ~0.3% max, C, N, H each <0.1%. No intentional alloying elements. Basically, it's pure titanium with controlled interstitials.

Comparison to Other Grades:

Vs Grade 1: Grade 2 is stronger (higher O content) but slightly less ductile. Grade 1 is used when you need extreme formability, whereas Grade 2 is used for a balance of strength and ductility

Vs Grade 5: Grade 5 (Ti-6Al-4V) absolutely outclasses Grade 2 in strength (Grade 5 has ~3× the tensile strength of Grade 2). However, Grade 2 wins in formability, weldability, and corrosion resistance (especially in environments like chemical processing where pure titanium's absence of alloying elements avoids certain corrosion mechanisms). Grade 2 is also non-alloyed, so it's fully biocompatible and slightly easier to weld (no concerns about aluminum/vanadium segregations).

Vs Grade 4: Grade 4 is the strongest CP, about 20–30% stronger than Grade 2 due to even higher oxygen. But that also makes Grade 4 a bit more challenging to form. Grade 2 sits in the sweet spot as the “workhorse CP grade."

Vs Alloys in general: Grade 2 can be thought of as the benchmark for corrosion resistance – alloyed grades may have comparable corrosion in many environments, but if you're designing for harsh chemicals, CP titanium is often preferred.

Grade 2 vs. other grades – Tensile Strength: The chart above shows Grade 2's typical tensile strength (~345 MPa) compared to some other common grades. You can see Grade 2 (orange bar) is much stronger than Grade 1, but significantly weaker than alloyed grades like Grade 5. However, remember that strength isn't everything – Grade 2 excels in flexibility and chemical durability where those stronger grades might not be as easy to use.

Common Forms & Applications:

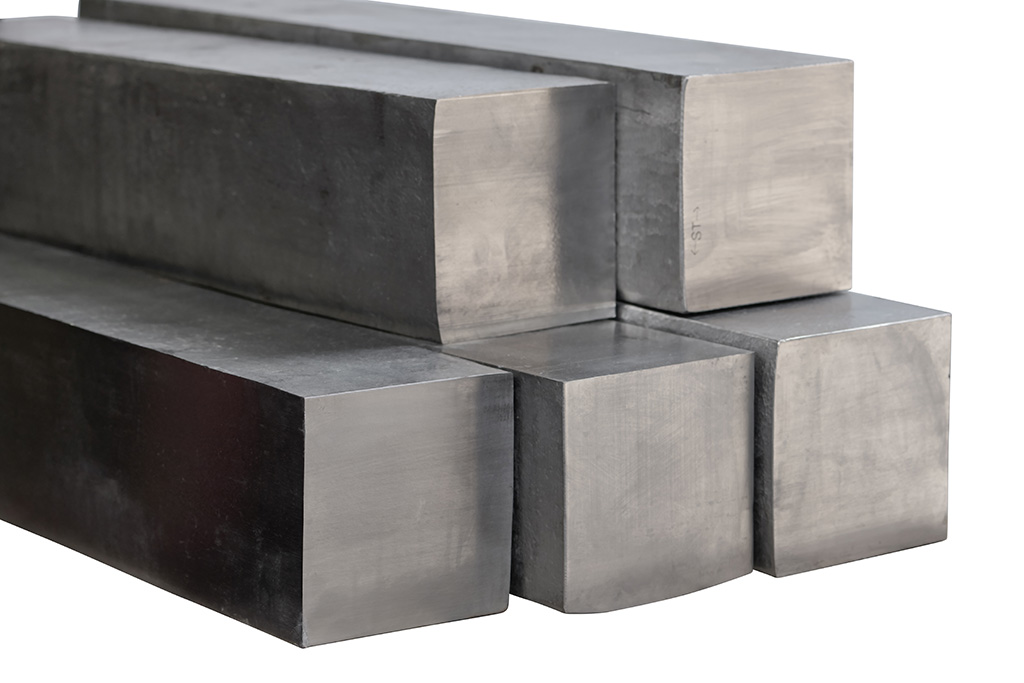

Available Forms: Grade 2 is readily available in all mill product forms. You can get Grade 2 sheet and plate (widely used in industry), round bar and blocks for machining, tubing for pipes and heat exchangers, and even wire for things like mesh or springs. It is one of the most stocked grades at TMS due to its versatility.

Industrial Applications: Grade 2's top use is in chemical processing equipment. For example, it's used to fabricate tanks, pipework, and heat exchanger tubes in petrochemical refineries, where corrosive fluids would eat through stainless steel. It's also common in power plants (for condenser tubing in seawater cooling, Grade 2 is great due to resistance to saltwater). Desalination plants and marine environments also use a ton of Grade 2.

Medical Applications: Grade 2 (and Grade 1 or 4) are used for things like implantable devices (dental implants, bone plates) when alloyed titanium isn't necessary. Because it's CP, it has no alloying elements that could cause reactions – making it very biocompatible. It's also used for surgical instruments that need non-magnetic properties (e.g., tools used in MRI rooms).

Aerospace Applications: You'll find Grade 2 in aerospace primarily in non-critical components that need corrosion resistance. For example, some aircraft use CP titanium for firewall insulation plates (taking advantage of titanium's heat resistance and non-flammability). Also, Grade 2 or 3 might be used in airframe brackets and clips in older aircraft designs. Spacecraft and satellites use CP titanium for fuel tank liners and plumbing because of its compatibility with propellants.

Consumer Products: Don't overlook everyday uses: high-end bicycles sometimes use Grade 2 for frames or parts (though Grade 9 is more common). Titanium eyeglass frames can be CP titanium because they're hypoallergenic and easy to flex. Even kitchen equipment like titanium cookware or camping gear might use CP grades for their non-toxic, non-corroding nature.

Working with Grade 2:

Grade 2 is known to be easily weldable – you can TIG weld it with standard technique (just ensure good argon shielding to prevent oxygen pickup). It can be cold formed much more readily than Grade 5; tight bends and complex shapes are possible (it behaves somewhat like stainless steel in forming). Machining Grade 2 is not difficult either, though it's still “gummy" compared to steel – sharp tools and slow speeds are recommended.

Grade 2 is known to be easily weldable – you can TIG weld it with standard technique (just ensure good argon shielding to prevent oxygen pickup). It can be cold formed much more readily than Grade 5; tight bends and complex shapes are possible (it behaves somewhat like stainless steel in forming). Machining Grade 2 is not difficult either, though it's still “gummy" compared to steel – sharp tools and slow speeds are recommended.

Fun Fact: In the 1960s, the USS Halibut (a US Navy submarine) had a Grade 2 titanium deep-sea camera housing added to it for covert operations, because titanium could withstand ocean depths that steel could not. That Grade 2 housing sat unseen in saltwater for months at a time without corroding. It's a testament to Grade 2's reliability that when you need something to last in a tough environment, pure titanium is an excellent choice.

(Another neat fact: Grade 2 and other CP titanium can actually heal itself in a way – if scratched, the exposed titanium immediately oxidizes and repassivates, stopping further corrosion. It's like a material with instant scab-forming ability!)